Creating by Japanese

Interior Designer

Who is traveler and working in Milan, German, Taiwan, China and Japan

“We use all resource

to imitate the wood to save them”

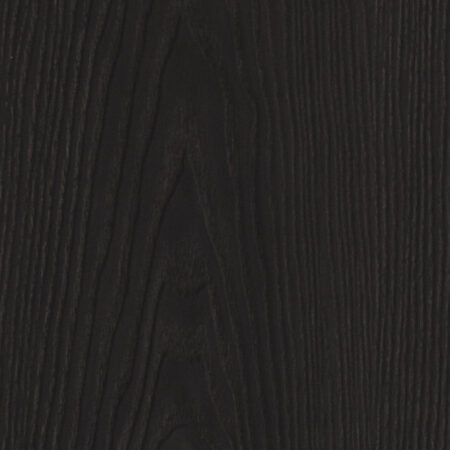

Veneerplast

CONCEPT

VENEER + PLASTIC

Reduce usage of paper (tree) 50%

you got the same thing.

DESIGN + MATERIAL SCIENCE

The better way of saving

is using the old one

ECO + DESIGN

We do best, to save you

and save the tree.

Why 0.3 mm?

Veneerplast use minimum possible to reduce the use of paper

Our calculation with Veneerplast

we can use 60% less of paper compare to other solid surface

Weight reduce

while reduce weight in transportation 50%

Looks better

And the user got a beautiful surface even better than before.

“The real

as veneer

and easy as a sticker”

Veneerplast

What is Veneerplast?

Veneerplast, a Synthetic of wood pattern decoration, aims to accomplish the perfect performing of decorative woods with new innovation methodology. Intentionally to have the highest level of realistic, fashionable and completely neat, Veneerplast is not only can be transferred decorative wood atmospheres but also minimal created possible burden to our beloved earth.

BLOG

Care and Maintenance

To make Veneerplast last long as it looks in the...

Read MoreHOW TO USE

Simply way to install Veneerplast. You install Veneerplast directly to...

Read MoreHello world!

Welcome to WordPress. This is your first post. Edit or...

Read MoreBLOG

Useful Tips

Just use normal stationary like a scissors or cuter to...

Read MoreSafety Caution

For safety, please follow the instruction while using; Be caution...

Read MoreCare and Maintenance

To make Veneerplast last long as it looks in the...

Read MoreHOW TO USE

Simply way to install Veneerplast. You install Veneerplast directly to...

Read MoreHello world!

Welcome to WordPress. This is your first post. Edit or...

Read More

Good for difference

Veneerplast thickness is only 0.3 mm that can be easily curved and bended in any design crafts. Imagination designers are unlimited with a high quality imitating surface wood that most as natural as real wood. Touch and feel never be compromise in using this synthetic wood.

Good for you

Veneerplast production uses only a certify resin that are less toxic possible than other real Veneers. You can enjoy being with environment friendly material and also got the feeling of wood sense as well.

Good for earth

Veneerplast with a concept of use less for more, its consist of less fiber cellulose than HPL over half, its has light weight and consume energy less than other surface materials. The finished product is need no further painting work that benefits more in waste and toxic from its activitiesGuideline installation

Good for Designer

Designer imagination comes true, we are looking for more than just a surface, 3D or curve or bend. it will be more possible and challenge with Veneerplast

The realistic looks will impress customers feeling and touching like surrounding of the real wood, color matching is more easy from our choice provided.

Good for Installer

Save in time, We all know that a contractor’s time is precious, there just aren’t enough hours in the day to get done everything you had planned. That’s why Veneerplast with the 0.3 mm thickness is such great, tools, reducing installation times by around 40% when compared to traditional HPL methods. Moreover, Veneerplast is easy to bend and very flexible for installation that make edge less visible to be seen. In work production, Veneerplast is cut by simple tools such as scissors and cutter. These all allows edge of any decor to be easy and simple to do.

Product Layers

Good for Installer

Save in time, We all know that a contractor’s time is precious, there just aren’t enough hours in the day to get done everything you had planned. That’s why Veneerplast with the 0.3 mm thickness is such great, tools, reducing installation times by around 40% when compared to traditional HPL methods. Moreover, Veneerplast is easy to bend and very flexible for installation that make edge less visible to be seen. In work production, Veneerplast is cut by simple tools such as scissors and cutter. These all allows edge of any decor to be easy and simple to do.